What is Dual In-line Package (DIP)?

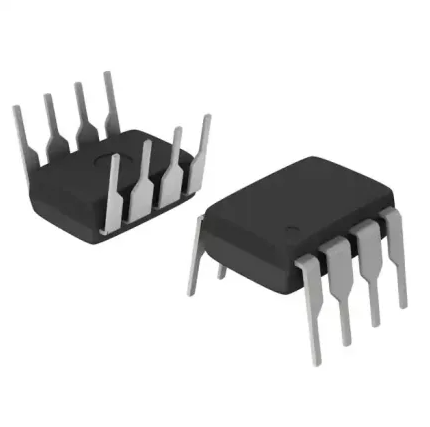

The Dual In-line Package, commonly known as DIP, is a classic and widely-used package type for electronic components. It plays a foundational role in the packaging of integrated circuits (ICs), providing a reliable and compact arrangement of pins for connecting to circuit boards. Let's delve into the key aspects of DIP to understand its design, variations, and applications.

1. Basic Design:

Physical Configuration:

DIP features two parallel rows of electrical connecting pins on opposite sides.

The pins are arranged in a standard grid pattern, facilitating easy integration onto circuit boards.

Package Types:

DIP-8, DIP-14, DIP-16: Denotes the total number of pins.

Through-Hole DIP (THDIP): Standard version with pins passing through the board.

Surface Mount Device (SMD) DIP (SMDIP): Designed for surface-mount assembly.

DIP comes in various configurations, including:

2. Pin Configuration:

Numbering Convention:

Pins are typically numbered sequentially.

The numbering starts from a designated corner or a notch, providing a reference point.

Standard Pin Count:

DIP packages come with varying pin counts, such as 8, 14, 16, 18, and more.

Commonly used for ICs, microcontrollers, and other digital or analog components.

3. Through-Hole vs. Surface Mount:

Through-Hole DIP:

Traditional version with pins passing through holes in the circuit board.

Manual or automated soldering secures the component to the board.

Surface Mount DIP:

Designed for modern, space-efficient assembly techniques.

Soldered directly onto the surface of the circuit board.

4. Applications:

Integrated Circuits (ICs):

DIP is a prevalent package type for ICs, housing a range of functions in various electronic devices.

Microcontrollers and Microprocessors:

Found in embedded systems, DIP packages accommodate microcontrollers and microprocessors.

Analog and Digital Components:

Used for a broad spectrum of analog and digital components like operational amplifiers, timers, and voltage regulators.

Educational Kits:

DIP packages are commonly used in educational electronics kits due to their ease of use and handling.

5. Advantages:

User-Friendly:

DIP packages are easy to handle, making them ideal for prototyping and educational purposes.

Versatility:

Available in various pin counts, accommodating a wide range of component types.

Cost-Effective:

Manufactured in high volumes, contributing to cost-effectiveness.