Expand Your Knowledge On Expansion Bolts!

What Is An Expansion Bolt?

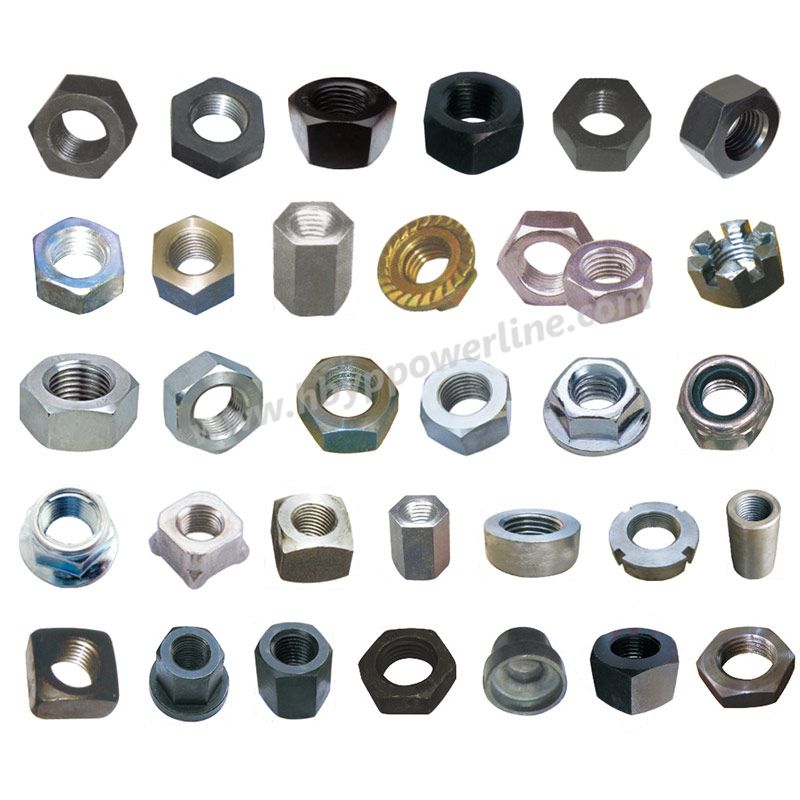

The term 'expansion bolt' refers to an assembly that consists of three fastening components: an expanding sleeve, a threaded bolt and a properly sized nut. When employed together, the force generated from tightening the nut and bolt pushes the expanding part of the sleeve outwards, gripping the material the sheathing is embedded into. Due to the specific fastening system, this type of bolt is most suitable for connections between porous materials, such as brick, stone, or concrete.

Types Of Expansion Bolts

Given the fastening mechanism, it's clear that expansion bolts are typically employed in applications where standard threading cannot be created. In spite of the numerous similarities that it shares with the nail-in anchors featuring nylon sleeves, these bolts are utilized in heavy-duty applications such as stadium seating or securing pews. There are several expansion bolt assemblies available, each serving a different role:

Lifetime Expansion Bolts: As their name suggests, these fasteners are designed to never be removed. They can be identified by the steel cone covering the head of the bolt.

Permafix Security Expansion Bolts: Commonly used to secure bars and grilles in place.

Anti-Tamper Expansion Bolts: Made from steel, the fasteners can be installed and removed via an anti-tamper tool.

The Lead Sleeve

In spite of the fact that all components are important, the lead sleeve is considered the heart of the expansion bolt assembly. The main reason why these bolts do such a great job at filling in the gaps in masonry, brick, or concrete, is that the sleeve is made of lead. The soft metal properties of lead make it compliant when pressure is applied to it. Because lead is malleable, the sleeve doesn't just fill in the existing cracks, but creates more than one anchor point, providing more stability. Since the soft metal doesn't rely on a single point of attachment, it also means fewer chances of cracking or shattering.

Expansion Bolt Assembly Advantages

Expansion bolts are not only flexible and pliable, but they are also reliable and strong. Perhaps the most appreciated feature is that they are not dependent on the quality of the materials used. For instance, in the construction industry, you can be certain the expansion bolt will continue to do its job, regardless of the quality of the concrete or brick.

A further appreciated feature of expansion bolts is that they allow some room for error. Referring to the construction industry again, these fasteners are flexible enough to ensure a safe installation, despite the fact that the drilled holes present minor misalignments.

Suggested reading:

How does a stop-start battery work in a car?

Lithium Cell Pilot Line: Revolutionizing Energy Storage

What Does a CBB60 Capacitor Do?

Sourcing Reliable Electronic Components: A Buyer's Guide

Jump Starter, the Game-Changer in Vehicle Emergencies

What are the key advantages of using Rockchip SOM?

How Vertiv Liebert UPS Works for Continuous Power Protection?

How to Use Expansion Bolts

Step 1

Determine what size expansion bolt is required for your application. A common installation of securing the metal legs of a machine to a concrete floor, for example, might require one expansion bolt per leg, with each expansion bolt 3/8 inch wide by 3 inches long.

Step 2

Mark the location of the expansion bolt locations on the floor--this is where the bolt will be secured to the floor. Most heavy-duty machines have holes pre-drilled in their feet (legs) for just this purpose. Mark the location of all anchors on the concrete at one time with a marker, so that they are all aligned correctly relative to one another.

Step 3

Drill the proper size and depth hole for each anchor. The correct size of the hole will be supplied by the manufacturer of the anchor bolt, usually labeled right on the box. A rule of thumb is that for a 1/4 inch anchor, use a 1/2 inch drill bit; for a 3/8 inch anchor, use a 5/8 inch drill bit, etc. The depth of the hole is determined by making sure the nut can attach to the bolt (anchor) with enough threading remaining so that it can be torqued sufficiently (usually two complete 360-degree turns of the nut).

Step 4

Insert the anchor into the hole. Make sure the anchor is resting at the very bottom of the pre-drilled hole before proceeding. Gently tap the anchor (using a hammer) until you are sure it is in its proper position. Remove the nut from the anchor. Next, insert the anchor tool onto the top of the buried anchor (the tool will be included with the anchor(s) kit). Strike the anchor tool firmly three or four times, which will expand the anchor sleeve enough to allow the expansion process to begin once the nut is tightened.

Step 5

Insert the bolt through the device is secured and then into the anchor (which is still buried). Tighten the nut to the desired amount of torque, or until it is tight if no torque specifications are available.

Since the construction industry is one sector that relies on expansion bolts for fastening, it's only natural to ask yourself whether the bolts can withstand the elements. The corrosion resistance is ensured by the steel alloys along with the zinc and cadmium plating. They are a great choice for construction as well as applications where the bolts face exposure to water.

Related News:The Distinction In Between Anchor Bolt And Bolt

What does a capacitor do to voltage?

Demystifying Types and Applications of Resistors

The Importance of Fully-Functional Traffic Lights - HDFC Ergo

What is the difference between RF cable and coaxial cable?

Phone Chargers: Powering Your Devices Anytime

Understanding Deep Cycle Battery Packs

Choosing the Right Wire Wound Resistor for Your Electronic Projects